Measuring accuracy

- Control of straightness and roundnessAt STAINLESS FRÜCHTL, we extend the limits of precision with an innovative measuring method that guarantees rigorous control of the straightness and roundness of bars. Thanks to this technology, we are able to deliver measurement results of the highest possible precision.

Advanced technology for all your measurements

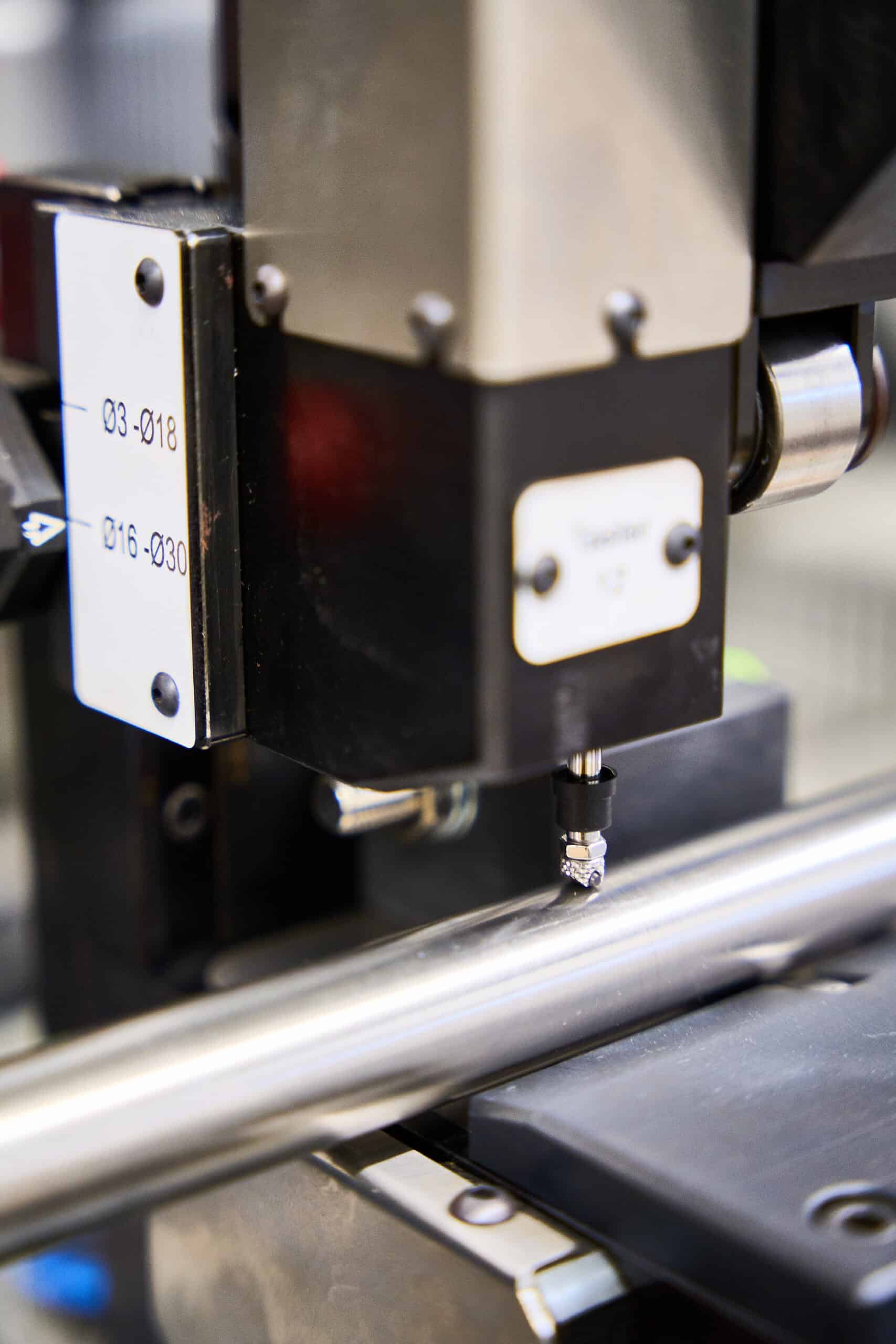

Our measuring system is based on a radial rotation probing process, enabling us to analyse our bars with precision:

- Straightness control: we measure the straightness of bars with a diameter of 3 to 30 mm, up to a length of 4.5 metres, with a maximum tolerance of 0.1 mm per metre.

- Roundness analysis: our machine detects deviations in shape with an accuracy of 1 µm, guaranteeing optimum quality.

- Recording of measurements: every check is accurately recorded, giving our customers total transparency over the characteristics of their materials.

A guarantee of high quality for our customers

Thanks to this advanced measurement technology, we can assure our customers that the raw material they use perfectly meets their requirements and the most stringent quality standards. Every bar inspected conforms to the specified tolerances, guaranteeing reliable, high-performance production.

Improve your manufacturing processes

Perfectly straight bars are not only a guarantee of quality, they also play an essential role in optimising your machining processes. That’s because:

- They protect your machine tools by reducing vibration and mechanical stress during turning.

- They extend the life of your tools, limiting maintenance and replacement costs.

- They improve machining precision, guaranteeing parts that meet specifications right from the first operation.

STAINLESS FRÜCHTL : The reference for precision

Our commitment to innovation and quality makes STAINLESS FRÜCHTL a trusted partner for manufacturers who demand perfect control of their materials. Thanks to our exclusive measuring technology, we can guarantee metal bars that meet the highest standards in terms of straightness and roundness.