1.4441 - 316LVM - ASTM F138 - ASTM F139

Description

Grade 1.4441 is remelted using an ESR-type consumable electrode, which increases its cleanliness and homogeneity. These advantages are essential to guarantee high fatigue strength, biocompatibility and very good corrosion resistance.

Stainless has a wide range of qualified sources in stock, as well as different product formats and conditions to meet your application needs.

This product can also be custom-made or cut into billets by our service centres. Each material is delivered with its certificate of origin to guarantee total transparency and traceabily

Main applications

Thanks to its biocompatibility and non-magnetic properties, which are recognised in the medical field, the grade is mainly used in the manufacture of implants, most often obtained by machining. The material is available in annealed, medium-hard or extra-hard form for smaller dimensions.

Metallurgy

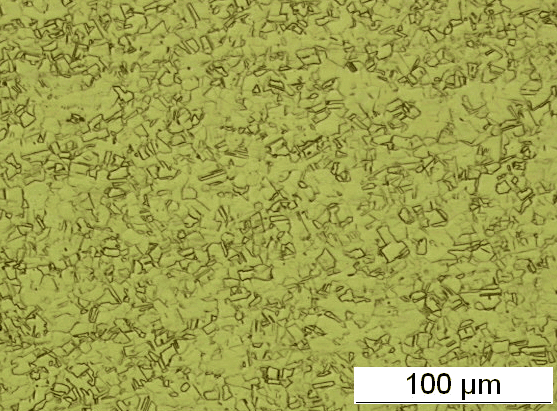

The manufacturing processes combined with the transformation processes result in a homogeneous microstructure with a fine grain size of at least index 5. See micrograph below in the annealed condition:

Machinability

Forgeability

The grade can be hot forged in the 900/1150°C temperature range. Annealing should be carried out after forging to restore the microstructure (dissolution of carbides).

Polishability

The high level of inclusion cleanliness and the homogeneity of the microstructure of this grade allow optimum polishing.

Heat treatments

Annealing at between 1050 and 1120°C followed by rapid quenching can be carried out after forging to restore corrosion resistance in particular, but no heat treatment is used to harden the grade.

Corrosion resistance

The grade is highly resistant to both general and pitting corrosion, thanks to its high molybdenum content combined with its low inclusion rate.

Standard Sizes

Round bars annealed, medium-hard or extra-hard depending on diameter – Hardened or ground surface

Annealed or work-hardened plates -Flat bars customised in annealed condition (consult us)

Other fshapes: please contact us